Coal Stockpiles and BTU Losses

Most folks in the bulk material handling business are well aware of the dust mitigation benefits offered by a well-designed wind fence. After all, wind fences have been in use for decades as an effective dust control strategy, across multiple stages of the material supply chain. But our friends in the coal-producing world know of another plight endemic to coal storage – BTU losses. For coal handlers, that same wind fence mitigating dust emissions by 50%+ can reduce annualized BTU losses by nearly 20%. And friend, that’s a lot of BTUs…

For the uninitiated, BTUs are a unit of heating capacity, based on the energy required to raise one pound of water by 1°F. In the context of coal-fired power generation, BTUs refer to the carbon content of a given sample of coal fuel stock – simply put, more carbon equals more fuel for combustion, equals more BTUs. The problem is that as soon as it is extracted from the Earth, coal begins a slow, natural degradation process whereby combustible carbon chains react with atmospheric oxygen to reduce the material’s heating capacity.

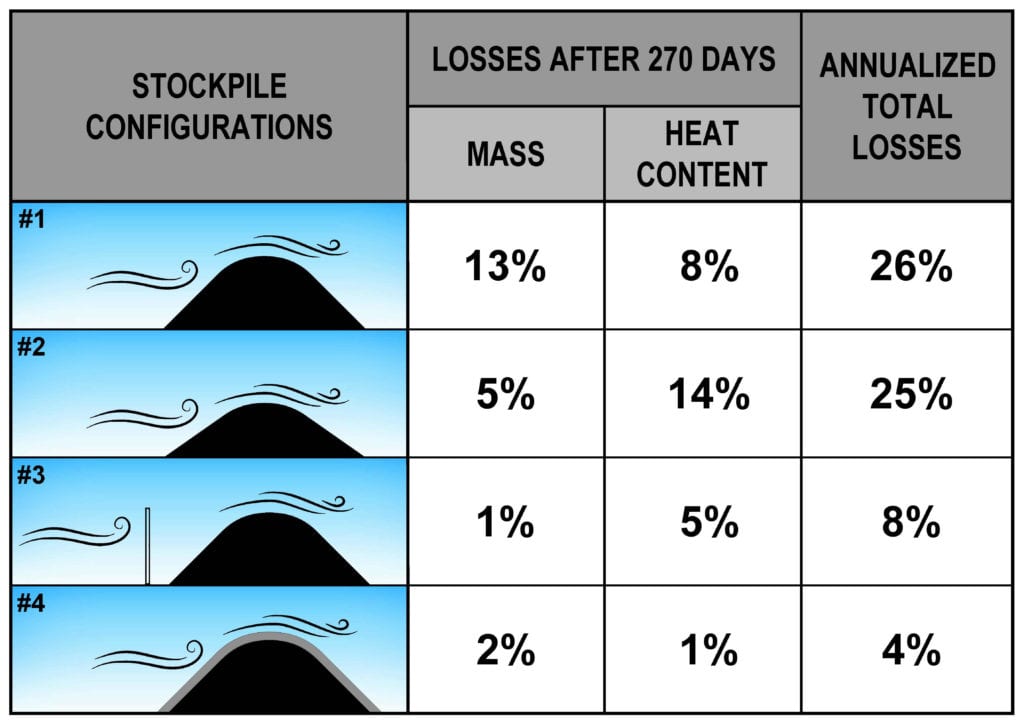

Operators at coal-fired power plants have long known that the mantra “fresh is best” is just as applicable to the coal they load in the boiler as it is to the produce they pick in the supermarket. But just how much of a difference does ‘freshness’ make? Scientists looking to provide an answer to this question conducted a study at an Endesa power plant in Spain. They evaluated four different pile configurations, including one with a wind fence, and assessed BTU losses for each after a monitoring period of at least 190 days. The four configurations were as follows:

⦁ Standard coal stockpile: truncated pyramid shape, with 45° sloped sides

⦁ Truncated pyramid shape, but with 25° sloped sides, giving the pile a lower profile

⦁ Same arrangement as #1, but sheltered from the wind using a wind fence constructed of pine boards

⦁ Same arrangement as #1, but sealed with fly ash & water slurry

The study made note of the fact that when evaluating BTU losses of a coal pile, there are both physical and chemical mechanisms at work. Physical losses pertain to material erosion caused by wind, and chemical losses pertain to heat content lost to oxidation. The table below compiles the numerical findings from the study, monitoring periods ranged from 190 days to 270 days. In the last column, the losses have been annualized and totaled for the purposes of comparison.

Unsurprisingly the configurations with physical membrane protecting the coal pile (i.e., configurations #3 and #4) performed the best, and by notable margins. The data suggest that configuration #4 performed marginally better than configuration #3, but the practicality of maintaining the fly ash & water slurry covering, while still accessing the pile material, raises its own efficiency concerns.

Perhaps the most revealing insight in the Enseada study is the inverse relationship in physical and chemical losses from configuration #1 to #2. The low profile pyramid in configuration #2 is effective at reducing wind erosion compared to the standard pyramid in configuration #1; however, the low profile configuration also exposes more pile surface area to a fresh supply of oxygen, thereby increasing the rate of coal oxidation. This process explains why heat content losses for the low profile pyramid nearly doubled relative to the standard pyramid.

The moral for coal plant operators is that pile shaping alone is not an effective strategy at mitigating BTU losses from coal stockyards. If you want to effectively reduce BTU losses at your facility, without significant disruption of operational efficiency, a professionally designed wind fence is the proven, practical solution. Having sheltered coal stockpiles on five different continents, WeatherSolve has the experience and the expertise to help you improve plant efficiency and ultimately save money on power generation. For your complimentary site evaluation and cost estimate, please email us at info@weathersolve.com.

Sources:

Energy Education – Coal fired power plant

Mining Technology -Metallurgical coal demand to be the worst hit in 2020

Hinrichs and M. Kleinbach, “Electricity: Circuits + Superconductors,” in Energy: Its Use and the Environment

For more information on a customized solution for your business contact WeatherSolve Structures today!