Boost Efficiency, Safety, and Sustainability with Advanced Wind Fence Solutions for Superior Dust Control

Developing and implementing effective dust management strategies is a primary objective in many industries worldwide. Fugitive dust generated by wind, material processing, and handling can negatively impact site operations, employee and public safety, regulatory compliance as well as the environment. In many instances operational and manufacturing processes can result in the dispersion of copious amounts of dust and requires a well-planned strategy to effectively manage. Of the dust suppression methods available, wind fences (also known as a wind break) emerge as a highly effective solution to overcome these challenges. In this article, we will explore the top 10 benefits of implementing a wind fence for dust control.

What is a Wind Fence?

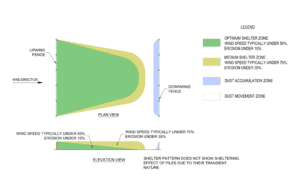

A wind fence is an engineered porous barrier erected to alter wind patterns and mitigate dust dispersion. By disrupting wind flow, these fences can decrease wind speeds by up to 80% in localized areas and 50% over larger expanses. A fence that is placed relatively perpendicular windward to the protected area is referred to as an upwind fence. An upwind fence redirects the wind up and over the fence while allowing a small amount of air to still pass through the fence. This creates a sheltered zone on the leeward side of the fence that extends for 8 to 10 times the height of the fence. The sheltered zone has significantly reduced wind velocity which allows dust to settle quickly. The small amount of air that passes through the fence equalizes the differential pressure and minimizes the formation of turbulence and wind eddies that are commonly seen with the erection of a solid windbreak. Conversely, when a wind fence is placed relatively perpendicular to outgoing winds, it is referred to as a downwind fence. A downwind fence acts as a catch fence and has a small sheltered area in front of the fence that allows dust particles to drop out of the air and collect. A small amount of the dust will still pass through the fence, but quickly falls to the ground in the protected zone on the leeward side of the fence, just as with the upwind fence. As wind directions change, an upwind fence may function as a downwind fence and a downwind fence may function as an upwind fence. The image below illustrates how both upwind and downwind fence’s function.

What Makes a WeatherSolve Wind Fence Different?

WeatherSolve Structures are the industry leader in the design and manufacturing of cutting-edge environment control structures. With over 40 years of expertise, their innovative designs incorporate the use of specialized fabrics and a proprietary stress-release clip system that acts like a zipper to release the bottom of a wind fence panel during extreme wind conditions. This reduces the overall load on the fence and prevents structural failure. Each WeatherSolve wind fence is engineered and tailor made to fit the unique challenges of each individual site.

Top 10 Benefits of a Wind Fence

1. Improved Dust Control

A wind fence can reduce fugitive dust to less than 1/8th that of an unprotected situation. By acting as a permeable barrier to wind, a wind fence can prevent dust from being lifted and becoming airborne, which could wreak havoc onsite operations and the environment. Wind fences improve dust control by:

-

Reducing Wind Speed

– A wind fence alters wind patterns by redirecting wind over the fence, thus creating a sheltered zone on the leeward side of the fence. The sheltered zone has significantly lower wind speeds which prevents dust from becoming airborne and causes already airborne dust to settle.

-

Controlling Dust Dispersal

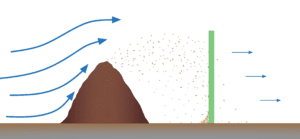

– By diverting wind patterns, a wind fence substantially reduces saltating dust through the reduction of particle speed. Saltation is the movement and migration of bouncing dust particles on or near the ground in a turbulent flow of air. The sheltered zone created on the leeward side of the wind fence also prevents the uptake of dust and allows air borne dust to fall to the ground. A downwind fence catches dust on the windward side and prevents it from spreading to surrounding areas negatively impacting the environment and public health and safety. The image below illustrates how a downwind fence functions to prevent dust dispersion.

-

Improving Surface Stability

– Wind fences aid in the stabilization of soil and reduce erosion of product in industry. An upwind fence effectively keeps wind off the surface of stockpiles causing fewer particles to detach and blow away. A downwind fence catches dispersed product and prevents it from spreading. The reduction of wind velocity also lessens the drying effect on soil which reduces dust generation in agricultural settings.

2. Always Operational with Little Maintenance

Wind fences are always operational. They require no mechanical parts which can seize up or break down. In addition, wind fences do not utilize any consumables or water and are easily installed and maintained. They are a hassle-free alternative for dust control measures.

3. Increased Operational Efficiency

Reduced dust on an industrial site means less downtime for equipment repair and employee absenteeism due to dust related issues. A well-designed, custom wind fence can reduce the amount of fugitive dust by upwards of 80% making for a cleaner, safer, and more productive work site. Wind fences improve operational efficiency by:

-

Reducing equipment downtime and maintenance

– Dust can cause unnecessary wear and tear on valuable equipment leading to frequent breakdowns, repairs, and cleaning. Dust creeps into engines causing clogs, overheating and engine failure. By reducing the amount of on-site dust with a wind fence, equipment operates more reliably and requires less maintenance.

-

Minimizing Product Contamination

– Dust can lead to product contamination from external dust and/or cross contamination from neighbouring stock piles which can detrimentally impact the quality of products. Mitigating dust with a wind fence leads to reduced contamination and improved quality outcomes.

-

Decreasing Cleaning and Maintenance Costs

– Dust accumulation leads to the necessity for frequent cleaning and site maintenance. These costs can add up quickly and eat into profits and operational budgets. Dust control with a wind fence results in less time spent on cleaning and maintenance activities.

4. Environmental Protection

With environmental issues becoming ever more critical in today’s society, wind fences offer a viable solution to reduce dust without the use of harmful chemicals or sprays. Wind fences protect the environment by:

-

Reducing Airborne Dust Pollution

– Reduced airborne dust helps to improve air quality and erosion.

-

Protecting Soil and Vegetation

– Through the reduction of wind speeds in the sheltered zone, a wind fence can prevent soil erosion thus protecting ecosystems and agricultural land.

-

Reducing Water Pollution

– In areas of strong winds, corrosive and harmful dust can be transported into nearby waterways causing contamination and pollution. A wind fence controls dust and reduces the amount of particulate matter from entering waterways, protecting water quality and marine life. It should be noted that on sites with heavy use of water sprays significant erosion of stockpiles may occur resulting in environmental pollution.

5. Compliance with Regulations

With an ever-growing emphasis on environmental stewardship in industry, regulatory bodies keep a watchful eye on dust mitigation operations. Hefty penalties and fines are levied on those who do not comply. Wind fences offer a dust control solution without the use of harmful chemicals to help businesses remain compliant with strict environmental regulations such as dust emission regulations and air quality standards.

6. Enhanced Aesthetic Appeal

Wind fences can be designed to blend in with the surroundings, improving the visual appeal of an industrial facility.

7. Adaptability to Different Environments

Unlike other dust mitigation strategies, wind fences can be used in any environment. Wind fences are adapted to the environmental setting through:

-

Customization

– Wind fences can be tailor made to meet specific environmental and operational needs. A custom fence is effective in diverse settings and environments, from small residential needs to large industrial sites and from extremely cold to extremely hot geographical locations.

-

Material Options

– Wind fences can be made from a variety of materials to suit the needs of the site.

-

Use of Advanced Materials

– Specialized porous fabrics composed of high-density polypropylene or polyethylene with UV protection, flame-retardant and corrosion resistant properties allow wind fences to be utilized in most climates.

8. Cost-Effective Solution

Wind fences offer a cost-effective alternative for dust control by:

-

Reducing Maintenance Costs

– Unlike costly chemical applications for dust control, wind fences offer cost savings and a considerable return on investment by reducing long term costs. There is no need for the use of consumables, frequent application of products or frequent servicing that is seen with other dust control measures. For more information on wind fence return on investment, see our blog “Harnessing the Wind: Exploring the ROI’s of a Wind Fence”.

-

Minimizing Resource Loss

– Wind can lead to the loss of valuable resources or minerals. Wind fences can substantially decrease the amount of assets lost from stockpiles due to being carried away by wind or contaminated by dust.

9. Improved Employee Health & Safety

Employee health and safety is negatively impacted by dust and air pollution. Severe respiratory conditions such as silicosis, chronic obstructive pulmonary disease, asthma and cancers may occur. In addition, the risk of injury is increased on sites where dust remains uncontrolled. Accumulated dust can result in slipping hazards while airborne dust can result in visibility issues. Dust controlled by a wind fence improves employee health and safety by:

- Reducing dust accumulation on surfaces and walkways

- Improving visibility and air quality

- Reducing employee injury and absenteeism

- Protection from extreme weather conditions

In windy environments, wind fences also function to prevent workers falling from elevated platforms.

10. Reduction of Equipment Damage

Fugitive dust can result in damage to costly equipment leading to frequent repairs and maintenance. Wind fences reduce damage to equipment through a variety of ways including:

- Preventing corrosion

- Decreasing abrasive wear

- Reducing dust related blockages

- Extending equipment lifespan

Key Points

Wind fences represent a transformative approach to dust management, offering numerous advantages that go beyond mere dust control. By effectively mitigating wind speed and dust dispersal, wind fences enhance operational efficiency, protect the environment, and ensure compliance with regulations. Their adaptability to various environments and ease of installation makes them a versatile solution suitable for a wide range of applications, from industrial sites to residential areas. Additionally, their cost-effectiveness and ability to improve employee health and safety underscore their value as a practical investment. For any operation facing challenges with dust and wind, integrating a wind fence can lead to significant improvements in both performance and environmental stewardship

Claire Cowie is a seasoned Quality Assurance Manager with over two decades of experience in healthcare and manufacturing. Her career began in pharmacy, where she led teams and honed her skills in quality management systems. As she transitioned to the manufacturing sector, her unique background combines a deep understanding of policy and quality assurance with a keen eye for quality control.

Claire has been instrumental in implementing and cultivating a comprehensive quality control program within WeatherSolve Structures. She has successfully integrated her pharmaceutical background with manufacturing best practices, particularly in areas such as Good Manufacturing Practices (GMP) and ISO 9001 standards. Her unique blend of experience continues to drive innovation and excellence in her role.