Dust Management Solutions

Wind Fences

A wind fence, or windbreak, is an engineered barrier constructed to alter wind patterns and mitigate dust dispersion. There are two modes in which wind fences are used to control dust: upwind fences and downwind fences. An upwind fence reduces wind speeds and minimizes dust movement, whereas a downwind fence catches dust that is still moving. As wind shifts and changes direction, upwind fences can become downwind fences and vice versa.

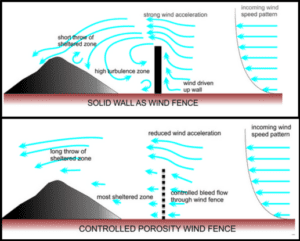

A wind fence is built by erecting a porous material as a barrier between the source of the wind and the area

to be protected. This produces a “sheltered” zone on the leeward side where the wind speed is drastically reduced. By allowing a small amount of wind to pass through the porous material, the wind break avoids the turbulence caused by a solid structure as shown in the image below. Downwind fences that are comprised of mesh fabric having openings greater than 25mm and/or those with gaps under the fence tend to be less efficient as the gaps allow the dust to escape. It is recommended that the fabric used for an effective wind fence be tightly meshed with a nibbed-wall base to prevent dust from passing through.

Other common wind fence materials include punched steel, wooden/plastic slats and various woven and knitted fabrics. Wind fences are effective in preventing both erosion and fugitive dust and it has been shown that a well-designed customized wind fence can reduce fugitive dust to one-eighth that of an unprotected situation. That’s a reduction of almost 88%!

In extreme wind erosion, over 90% of dust never reaches more than 1m above the ground surface, therefore; it is possible to see significant benefits in dust reduction with the installation of a down-wind or “catch” fence. Generally, down-wind fences with a minimum height of 1.5 times the height of the tallest dust source function as a drop-out zone for particulate matter. It should be noted that any height for a downwind fence is helpful but overall efficiency is dependent on the total wind and dust control plan.

Although effective, solid covers such as tarpaulin may also be used to help reduce loss from stock piles due to wind and provide protection against precipitation. Solid covers must be used carefully and not be opened on a windy day as this may result in product loss and increases the potential of the tarp blowing away.

It has been shown that unprotected or compacted coal stockpiles can lose up to 26% of their BTUs over the course of a year9. The following image shows the results of a study conducted to determine the deterioration of BTUs of coal storage in a stock pile9. The first image shows the control pile with 45-degree slope angles and without special protection or dust suppression. The second image shows a compacted pile. The third image shows a stockpile with a wind barrier, and the fourth with a slurry of “fly ash and water”9. It is evident that wind fences not only reduce dust and impacts of wind, but are also an effective protective measure against BTU losses in coal stock piles.

In addition, wind fences are an environmentally friendly effective dust control method as they require little maintenance and do not require any costly commodities such as water, electricity, or chemicals. They are ideal for multiple situations including controlling dust on both static and dynamic stockpiles.

Surfactants

Surfactants are chemicals that are added to water to help reduce water surface tension and capture dust particles through an increased ability to “wet” dust by the formation of fine droplets1. These chemicals are used near dust sources to agglomerate dust particles and cause them to settle. Studies have shown that surfactants suppress fine dust particles up to 125% more effectively than plain water3. Note that plain water is much less effective for dust control due to increased evaporation, erosion, and over-wetting of materials. Using a surfactant to increase the wetting ability of water results in the need for a chemical consumable to this dust control strategy.

The key to successfully using surfactants in preventing dust particles from entering the surrounding air is uniformity of spraying2. It is not so much the amount of spray that makes this dust control method effective, but rather, the way in which the surfactant is applied.

Fog Cannons & Fogging Systems

Fog cannons use a powerful fan to blow water mist into the air and capture airborne dust particles. This is accomplished by spraying pressurized water into the air via a series of jet nozzles which results in a fine atomized mist that suppresses airborne and surface dust. Fog cannons are ideal for locations where visible dust is a problem as the fine mist agglomerates particles in the air causing them to fall to the ground under the extra weight.

Surfactants may be added to the water in fog cannons should there be respirable particles in the air. The surfactants increase the wetting ability of water and more easily agglomerate with smaller dust particles. Fog also requires “hang time” with airborne dust particles and therefore this method is generally used in conjunction with an enclosure such as caging with fabric cladding or a wind fence to improve its ability to suppress dust. The cannons are designed to spray large water droplets which evaporate to the correct size by the time they reach their dust target. Note that the use of a custom wind fence to enclose the fog and decrease the impact of wind can substantially increase the efficacy of fog in dust control. It is recommended that a fog cannon be used in conjunction with a custom wind fence for optimal dust suppression results.

A fogging system for dust suppression utilizes strategically placed nozzles that may use compressed air to create high frequency sound waves that break apart water droplets into fog sized droplets that are dispersed into the surroundings to reduce dust through agglomeration8. They are generally placed at the source of dust generation, such as along conveyor belts or at transfer stations, to prevent dust from becoming airborne. As with fog cannons, the effectiveness of fogging may be increased when used in conjunction with a custom wind fence.

Foam Suppression

Foam suppression controls dust by preventing particles from entering the air. Water is combined with a foaming agent and, using compressed air, is emitted into the environment. The resulting foam barrier is formed on top of dust producing areas that is effective for days before reapplication is required. Studies have shown that foam technology can reduce dust in coal mines by up to 59.5%5. Foam suppressants also utilize less water than fog cannons and surfactants which reduces the risk of costly water damage and corrosion to equipment and buildings.

Natural Windbreaks

Natural windbreaks, or shelter belts, are comprised of trees and other foliage that act as a physical barrier to lower wind speeds and purify the air at ground level, thus reducing the level of airborne dust particulate matter6. Using vegetation to control dust is ideal as a low-cost alternative to areas with little to no vehicle traffic. Creating gaps in the wind break for vehicles decreases the effectiveness of the windbreak. Natural windbreaks are also aesthetically pleasing, and when paired with good ground cover, help retain moisture thus reducing dust generation in areas where erosion is prevalent. Unfortunately, there are some pitfalls when implementing and maintaining a natural windbreak. They may harbour pests, trash, and are slow to establish as a windbreak. In addition, natural windbreaks have varying porosity throughout the year and differences in height that impacts their consistency and efficacy. They are generally ineffective for storage situations such as static stockpiles.

Solid Barriers

Solid barriers act as a dust control measure for stockpiles by lowering wind speeds and reducing the amount of airborne particulate matter.

Solid barriers are exactly as you would expect, solid. They include structures and materials such as plywood, and other constructs that physically prevent the spread of dust. Solid barriers such as walls work best when stockpiles run up against them. Unfortunately, due to their solid nature, turbulence is created as the wind runs up the side and over the barrier resulting in a vacuum-like effect and sucking the dust back down. Solid barriers are effectively just a poor wind fence.

Buildings

Buildings offer another form of dust control as unwanted dust is stored within the building. An example of a building commonly used to cover ground piles, such as coal, are domes. These structures form a protective covering over the stockpile preventing harmful dust from being released into the environment as well as the additional benefit of protecting the product from precipitation and wind. Unfortunately, this method for dust control is very costly and creates a highly uncomfortable environment for workers.

Water Absorbing Products (Moisture attracting salts)

Calcium Chloride and Magnesium Chloride are two hygroscopic (water attracting) chemicals that are commonly used for dust control. These chemicals work by attracting moisture from the air to wet the ground (or stockpile) which in turn reduces the amount of dust particles that become airborne. Calcium chloride is more effective than magnesium chloride in hot arid climates as it does not dry out as quickly. Both are ideal for controlling dust on unpaved roads in areas that have high moisture content in the air.

Dust Control Insights

Dust control is a multifaceted challenge that requires a nuanced approach. The effectiveness of different methods can vary based on factors such as location, dust type, and environmental conditions. By understanding and applying the appropriate techniques, industries can significantly reduce the impact of dust on health and the environment.

From wind fences and surfactants to fog cannons and natural windbreaks, each method offers unique benefits and applications. Choosing the right solution involves assessing the specific needs of the site and the nature of the dust problem. Implementing a combination of these strategies can often yield the best results, ensuring a cleaner and safer environment for both workers and the community.

In addition to dust control methods, businesses can also take a proactive approach to reducing unwanted dust on a site. Easily spreadable dust from vehicles and other machinery can be reduced by frequent washing, sweeping, and truck wheel baths to avoid tracking dust from one area to another.

As dust emissions continue to rise, the importance of effective dust management cannot be overstated. By leveraging these innovative techniques and staying informed about new developments in dust control technology, industries can make significant strides in reducing dust pollution and protecting public health.

Written by Claire Cowey

References:

- “Surfactant Dust System” https://www.mining-technology.com/products/surfactant-dust-system/ Accessed July 31, 2024

- Kissell, Fred N. “Handbook for Dust Control in Mining” https://www.cdc.gov/niosh/mining/userfiles/works/pdfs/2003-147.pdf Accessed July 31, 2024

- 3. Kim, J. “Respirable coal dust control using surfactants – with special emphasis on a liquid spray system” https://scholarsmine.mst.edu/doctoral_dissertations/1075/#:~:text=More%20critically%2C%20the%20best%20surfactant,a%20hydrophilic%20state%20through%20adsorption Accessed July 31, 2024

- Chaulya, S.K., Chowdhury, A, Kumar, S. et al. “Fugitive dust emission control study for a developed smart dry fog system” Journal of Environmental Management. https://www.sciencedirect.com/science/article/abs/pii/S030147972100178X Accessed July 31, 2024

- Ji, M., Zhongguang, S, Guo, H. “The Application of the Foam Technology to the Dust Control for Reducing the Dust Injury of Coal Mines” Appl. Sci 2022 12(21). https://www.mdpi.com/2076-3417/12/21/10878 Accessed July 31, 2024

- Dust Control. https://www.epa.gov/system/files/documents/2021-11/bmp-dust-control.pdf Accessed July 31, 2024

- How Dust Affects the World’s Health https://earthobservatory.nasa.gov/images/151100/how-dust-affects-the-worlds-health#:~:text=The%20NASA%20team’s%20conclusion%3A%20exposure,and%20166%2C000%20from%20lung%20cancer. Accessed July 31, 2024

- https://www.raringcorp.com/technologies/adstm-dry-fog Accessed Sep 5, 2024.

- “Powermag” 12/01/2016 on results from Endesa Power Stn Spain https://www.powermag.com/who-moved-my-btus-the-pitfalls-of-extended-coal-storage/ Accessed Sept 16, 2024