Smooth Sailing: The Top 5 Financial Benefits of Wind Fences in Port Cargo Handling

Contents

Setting Sail for Stability: Wind Fences – A Brief Overview 2

1. Weathering the Storm: Reduced Operational Disruptions

2. Shielding the Bottom Line: Decreased Maintenance Costs

3. A Safer Harbour: Enhanced Worker Safety

4. Steady as She Goes: Community & Environmental Protection

5. Anchored Savings: Long Term Cost Savings

6. The Seas of Change

7. References & Reading Materials

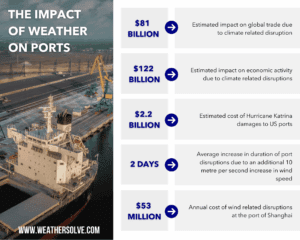

It isn’t always smooth sailing at industrial ports around the world. Wind is a harbinger of chaos; hindering operations and product handling resulting in lost profits, productivity and costly downtime. Port locations storing and handling bulk cargo are consistently exposed to the impacts of high winds and gusts. For context, the ports of Shanghai and Ningbo experience operational disruptions of 5 to 6 days per annum due to high winds1. Factor in that sea trade continues to grow requiring increased sea vessel size and port equipment. Now consider that ports continue to expand outwards from rugged shore lines. These are already highly windy locations due to the rugged terrain near sea sides and as ports expand to accommodate increasing vessel and equipment size, the impact of wind increases with the increase of these additional wind surfaces. And don’t forget about the ever-increasing number of severe weather and climate events each year. The overall impact? Severe disruptions, not just locally, but to global supply chains. Some studies estimate that $81B USD of global trade and $122B USD of economic activity is at risk annually due to climate related disruptions at ports1.

Setting Sail for Stability: Wind Fences – A Brief Overview

With the constant battle to maintain operational stability, protect workers, maintain fiscal viability and prevent product loss in windy port environments, custom wind fences emerge as practical and cost-effective solution.

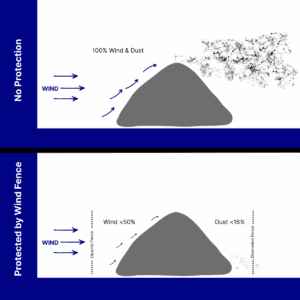

The primary function of a wind fence is to reduce wind velocity in a specific area in order to protect it from the impacts of strong winds. Wind fences are constructed by erecting a porous material to act as a barrier to reduce wind speed and mitigate dust. They are of particular benefit in port operations and cargo handling. The porous barrier reduces the impact of wind and significantly diminishes dust by two key modes: upwind fences and downwind fences. Upwind fences reduce the velocity of incoming winds thereby reducing wind-related damage and dust particle uptake in the sheltered area, whereas downwind fences “catch” dust that is still in motion. As wind directions change, an upwind fence may become a downwind fence, and vice versa. In an unprotected situation, wind blows up the side of a stockpile and causes particulate matter to become airborne. The smaller the particle, the further it spreads. A wind fence slows the wind while allowing a small amount of wind to pass through the porous barrier effectively equalizing the differential pressure on either side of the barrier. The result is a “sheltered zone” on the leeward side of the fence without the turbulence and wind eddies that are seen with the use of a solid structure.

For a well-designed wind fence with controlled porosity, wind speeds can be reduced by approximately 50-75% on the leeward side. Factors such as wind fence material, fence design, site topography, fence orientation, and size of the area to be protected must be considered to optimize results.

For further information on how a wind fence works visit our website at www.weathersolve.com or contact our experts at info@weathersolve.com or 1-800-749-2201.

1. Weathering the Storm: Reduced Operational Disruptions

Most ports have specific requirements for operational ability during windy conditions which are typically based on the Beaufort Wind Force Scale. The Beaufort Scale assigns the force of wind to a number which estimates wind intensity and is commonly used by ports to determine when to pause or completely halt operations to prevent accidents caused by high winds. Typically, operations are significantly impacted at Beaufort 6 and are fully stopped at Beaufort 8. At Beaufort 6, heightened safety measures are required to protect workers and maintain operations resulting in increased loading/unloading time and potentially ceasing crane operations. With extreme storms becoming more prevalent, wind will continue to negatively impact ports around the globe dealing a significant financial and economic blow.

Studies indicate that 40.1% of ports are exposed to extremes and natural hazards resulting in damage to infrastructure and operational disruptions 5. Of these hazards, tropical cyclone winds are estimated to have the largest impact on logistic losses and are “by far the most important hazard” at the Port of Shanghai 5. Wind related disruptions at the Shanghai port are reported to be $53 million USD per annum 2.

Wind fences have a proven track record of reducing wind velocity in port environments. A study conducted at a large port in China showed that wind fences reduced mean wind speed on average by 51.5% per annum and entrapped 50-80% of total suspended particles 3. Another study conducted at a coal terminal port in Eastern Europe corroborates these results, showing a reduction in coal dust concentrations of 58.6 – 81.3% 4.

WeatherSolve Structures has extensive experience providing solutions for wind and dust related problems at ports around the world. Our first example takes us to a port in South America where a solution was required for wind and dust control at a steel pelletizing plant. The site was exposed to high winds and with a large number of stockpiles, it was at risk of contaminating nearby metropolitan areas. WeatherSolve, in collaboration with Brazilian engineers, was tasked with engineering and designing a wind fence that would effectively manage the wind and dust on-site while not impacting nearby metropolitan areas.

For the purpose of validating and optimizing the proposed fence design, US engineers, under guidance from local consultants, were commissioned to conduct a computational fluid dynamics (CFD) study and projected a dust control level of 80% for the site. The end result was wind fencing with heights ranging from 15-28m and a combined length of nearly 9km. Custom woven polyethylene green fabric with 47% aerodynamic porosity was used for the wind fence panels providing excellent dust and wind suppression to reduce the impact on the site and surrounding area. Studies conducted on the fence following installation validated the level of dust suppression leading the client to commission multiple fence expansions for surrounding areas.

2. Shielding the Bottom Line: Decreased Maintenance Costs

There isn’t always a buffer of time or budgetary allowances in busy port and cargo handling environment to invest in the preventable maintenance of valuable equipment and infrastructure. Dust is insidious – creeping its way into engines resulting in clogged filters, decreased equipment efficiency and increasing maintenance frequency and costly repairs. The costs associated with dust related maintenance impact everything from operational efficiencies and labour budgets to regulatory compliance and equipment repair. Reducing dust at ports leads to reduced wear and tear on expensive equipment and diminishes downtime due to dust-related breakdowns. With wind fences demonstrating upwards of a 70% reduction in fugitive dust in a port environment, they stand out as a front runner amongst other dust suppression strategies with their minimal requirements for maintenance and no man power or consumables to operate at peak efficiency. Integrating a wind fence presents significant cost savings benefitting the bottom line for both operational and labour related budgets.

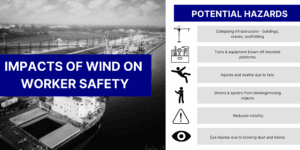

3. A Safer Harbour: Enhanced Worker Safety

Safety is top of mind for employees and companies alike when wind blows through port environments. Wind exposes workers to fall hazards, destabilized crane loads, blowing/falling objects and vehicular accidents. To top it off, those who work at marine terminals and port operations have a greater chance of fatality, injury and illness rates than other industries. The National Institute for Occupational Health and Safety (NIOSH) reported that the annual rate of fatalities was five times higher than the overall US workforce and double the number of injuries7.

Custom wind fences offer a viable solution to help shield workers from these hazardous conditions and prevent work related accidents and fatalities. A custom wind fence can reduce localized wind velocity by up to 75% which greatly diminishes the impact that high winds have on the protected area. In fact, gusts are effectively stopped in the optimally sheltered zone which improves both health and safety outcomes. Many jurisdictions have regulations regarding protecting workers in windy conditions. For example, the Occupational Health and Safety Association “considers wind exceeding 30-40 mph” as hazardous “unless the employer takes precautions to protect employees from the hazardous effects of the wind 8”. Wind fences create a stable working environment that protects workers from high winds allowing them to work in less dangerous conditions.

4. Steady as She Goes: Community & Environmental Protection

Blowing dust causes contamination of surrounding communities and damage to sensitive marine habitats at industrial ports around the world. Without proper dust mitigation strategies in place, public health and safety and marine environments are at risk. Product contamination and/or cross contamination between neighbouring stock piles is also a frequent occurrence at ports that negatively impacts the overall quality of products. In some extreme cases, improper dust control can have devastating outcomes. Take for example an explosion that occurred in Port Wentworth, Georgia USA in July 2008 as the result of combustible dust. The catastrophe claimed the lives of 14 and injured 38 others. The company was charged with 124 safety violations and doled out $6 million USD in fines. The cost to rebuild was estimated at $220 million USD 8.

The importance of controlling dust in a port environment must be emphasized. Not only are the impacts of uncontrolled dust grave to humans, the environment and infrastructure, but the financial impacts are significant. A proper dust mitigation management plan is a must for all dust producing port operations. Integration of a wind fence at port locations significantly reduces fugitive dust levels, and in some cases, can improve the efficacy of other dust control measures (e.g. fog cannons). While the exact reduction of combustible dust events, marine pollution and protection of health and safety due to implementing a wind fence has yet to be studied, it is clear that the substantial dust suppression that wind fences provide suggest they play a crucial role in enhancing the safety and environmental stewardship in port environments.

5. Anchored Savings: Long Term Cost Savings

Dust suppression can be a costly, never ending money pit. Many dust control strategies require costly consumables, significant energy costs and man power for peak performance. Bulk cargo handling, frequent loading and unloading of materials in addition to stockpiles contribute to the generation of unwanted dust. Fine particulate matter and erosion contribute significantly to product loss with many sites losing 3 to 15% of throughput yearly – profits are literally blown away in the wind. A well-designed wind fence provides an average reduction in fugitive dust of 70% which equates to enormous cost savings and an excellent return on investment. Consider YOUR annual throughput and quickly do the arithmetic to get an idea of how much savings can be realized. You might be surprised.

And don’t forget that wind fences offer a low maintenance alternative to other dust mitigation strategies offering effective wind and dust reduction without the need for consumables, energy or water. Once installed, they are a “set it and forget it” solution.

6. The Seas of Change

As the winds of change continue to blow through the global trade landscape, industrial ports are facing unprecedented challenges. The increasing frequency of severe weather events and the expansion of ports to accommodate larger vessels and equipment only exacerbate the impact of high winds and dust. Custom wind fences offer a solution to many of these issues. By effectively reducing wind velocity and fugitive dust, wind fences enhance operational efficiency, improve health and safety while protecting the environment.

In a world where the stability of global supply chains is more fragile than ever, the integration of wind fences serves as a critical strategy for ports seeking to navigate the unpredictable storms ahead. Ports can confidently weather the elements with greater resilience, safeguarding both their workforce and the communities they serve. As industries continue to evolve in response to climate change, these winds of change may no longer be a force of disruption but a catalyst for smarter, more sustainable port operations.

7. References & Reading Materials

1. Verschuur, J., Koks, E., Hall, J., “Systemic risks from climate-related disruptions at ports” Nature Climate Change 20 July 2023 https://doi.org/10.1038/s41558-023-01754-w

2. Van Houtven, G., Gallaher, M., Woollacott, J., et al. “Act Now or Pay Later: The Costs of Climate Inaction for Ports and Shipping” RTI International March 2022

3. Cong, X.C., Du, H.B., Peng, S.T. et al. “Field measurements of shelter efficacy for installed wind fences in the open coal yard”. Journal of Wind Engineering and Industrial Aerodynamics. Volume 117, June 2013, pp 18-24. https://doi.org/10.1016/j.jweia.2013.04.004

4. Moskovaya, I.V. et al 2017 IOP Conf. Ser.: Earth Environ. Sci. 87 042010 “Assessment of efficiency of windbreak and dust suppression walls for coal terminals”. https://iopscience.iop.org/article/10.1088/1755-1315/87/4/042010/pdf

5. Verschuur, J., Koks, E., Li, S., et al. “Multi-hazard risk to global port infrastructure and resulting trade and logistics losses”. Nature – Communications Earth & Environment (2023) 4:5 | https://doi.org/10.1038/s43247-022-00656-7

6. https://www.osha.gov/laws-regs/regulations/standardnumber/1926/1926.968#:~:text=Note%20to%20the%20definition%20of%20%22high%20wind%22%3A%20The%20Occupational,criteria%2C%20unless%20the%20employer%20takes Accessed Oct 9, 2024

7. National Institute for Occupational Safety and Health (NIOSH) “Marine Safety and Health” https://www.cdc.gov/niosh/maritime/about/marine-terminals-and-port-operations.html Accessed March 3, 2025.

8. NASA System Failure Case Studies “Dust to Dust”. February 2011 Volume 5 Issue 2.

9. Loredo-Souza, A., Schettini, E. “Wind Tunnel Studies on the Shelter Effect of Porous Fences on Coal Piles Models of the CVRD – Vitoria Brazil” 10th Americas Conference on Wind Engineering ACWE 2005

Claire Cowie is a seasoned Quality Assurance Manager with over two decades of experience in healthcare and manufacturing. Her career began in pharmacy, where she led teams and honed her skills in quality management systems. As she transitioned to the manufacturing sector, her unique background combines a deep understanding of policy and quality assurance with a keen eye for quality control.

Claire has been instrumental in implementing and cultivating a comprehensive quality control program within WeatherSolve Structures. She has successfully integrated her pharmaceutical background with manufacturing best practices, particularly in areas such as Good Manufacturing Practices (GMP) and ISO 9001 standards. Her unique blend of experience continues to drive innovation and excellence in her role.