Wind Fences for Sawmills & Timber Yards: Reduce Dust, Improve Safety, and Protect Profits

Contents

1. Don’t Let the Wind Blow Your Budget: Financial Benefits of Wind Fences for Sawmills & Timber Yards

2. Dust in the Wind? Not Anymore Thanks to Wind Fences

3. Turning Gusts into Gain: Wind Fences for a Healthier, Safer Workplace

4. An Easy-Breezy Solution to Prevent Product Loss: Wind Fences in Action

5. Improving Regulatory Compliance: Wind Fence’s to the Rescue

6. Wind Fences: The Investment that Pays You Back

7. Saving Sawdust: A Case for Wind Fences

8. Turning Dust Into Dollars: Revolutionize Your Sawmill

9. References & Reading Material

1. Don’t Let the Wind Blow Your Budget: Financial Benefits of Wind Fences for Sawmills & Timber Yards

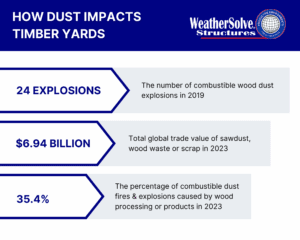

Most of us think of dust as a nuisance, but to timber yard and sawmill insiders, dust may as well be gold. Each year, the wood products industry exports billions of dollars in sawdust and wood waste to the tune of almost $7 billion dollars according to the OEC 1.

Wind fences offer an opportunity for timber yards and sawmills to decrease onsite dust and increase profit margins. Join us as we explore the financial benefits of wind fences in the wood processing and products industry.

2. Dust in the Wind?

Not Anymore Thanks to Wind Fences

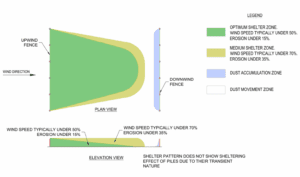

Before we begin, let’s have a quick refresher on wind fences. A wind fence is an engineered porous barrier erected to alter wind patterns and mitigate dust dispersion. By disrupting wind flow, these fences can decrease wind speeds by up to 80% in localized areas and 50% over larger expanses. A fence that is placed relatively perpendicular windward to the protected area is referred to as an upwind fence. An upwind fence redirects the wind up and over the fence while allowing a small amount of air to still pass through the fence. This creates a sheltered zone on the leeward side of the fence that extends for 8 to 10 times the height of the fence. The sheltered zone has significantly reduced wind velocity which allows dust to settle. The small amount of air that passes through the fence equalizes the differential pressure and minimizes the formation of turbulence and wind eddies that are commonly seen with the erection of a solid windbreak. Conversely, when a wind fence is placed relatively perpendicular to outgoing winds, it is referred to as a downwind fence. A downwind fence acts as a catch fence and has a small sheltered area in front of the fence that allows dust particles to drop out of the air and collect. A small amount of the dust will still pass through the fence, but quickly falls to the ground in the protected zone on the leeward side of the fence, just as with the upwind fence. As wind directions change, an upwind fence may function as a downwind fence and a downwind fence may function as an upwind fence. When it comes to timber yards, less dense wood dust tends to takes a lot longer to settle than more dense mineral dust. Unlike mineral dust, wood dust is fibrous and behaves differently in the wind. Think of falling wood dust as a leaf and falling mineral dust as a ball bearing. With this in mind, it makes sense that in timber yards, the key is to prevent dust from becoming airborne in the first place. This is where a wind fence has the greatest advantage. The image below illustrates how both upwind and downwind fence’s function.

3. Turning Gusts into Gain: Wind Fences for a Healthier, Safer Workplace

There are few industries where dust is such an omnipresent issue than that seen in timber yards and sawmills. Cutting, sawing, milling and turning – it seems that every task generates dust. Without effective management strategies in place, high dust levels not only threaten employee health and safety but operational efficiencies. Among the most prominent impacts of dust in wood-processing is the detrimental impact on worker

health. Wood dust can cause a plethora of illness and has been classified by the International Agency for Cancer Research as a Group 1 carcinogen – evidence of carcinogenicity in humans2. An Australian study estimates that 65% of workers employed in the manufacture of wood and wood products are exposed to carcinogens in the workplace 3 with cancers of the paranasal sinuses and nasal cavity being amongst the most prevalent4. Given that the cost per case of these cancers is approximately $500K – $700K5, the financial impact is clearly costly and far reaching. In Canada, it is estimated that 304,000 workers are exposed to the harmful effects of wood dust each year with sawmills in the lead with 56% of workers experiencing the highest exposure rates6. Skin and mucus membrane irritation, dermatitis and eye injury tend to be the most commonly observed issues stemming from larger dust particles (>10um) whereas smaller dust particles (<10um) are easily inhaled and may result in permanent irreversible damage to the lungs and respiratory tract.

Well-designed wind fences have demonstrated a reduction of fugitive dust to 1/8 th that of an unprotected situation. Wind fences drastically reduce airborne particulate matter by reducing wind speed in the sheltered zone and trapping fugitive dust without the need for potentially harmful chemicals and sprays or additional man power. As air quality increases, the health hazards associated with workplace dust decreases, leading to improved well-being of employees and reduced labor costs associated with dust related absenteeism.

4. An Easy-Breezy Solution to Prevent Product

Loss: Wind Fences in Action

Sawdust piles are a mainstay of mills and the wood processing industry. Once treated as a disposable by product of operations, sawdust has revolutionized the industry and is used in everything from particle board and insulation materials to biomass fuel production and animal bedding. Evidenced by information published by the OEC, the global sawdust market is estimated at $7 billion USD1 and $1.2 billion USD in sawdust drying applications7. Considered an alternative to fossil fuels, wood pellet consumption is on the rise with projections to meet 25% of the EUC’s energy demand by 2030 and driving the market growth of sawdust granulators to 150 million USD in 20248. There seems to be no end in sight for the ever-increasing demand for sawdust.

Sawdust is free spirited and doesn’t like to stay in one place for too long. Piles of sawdust quickly blow away as they are notoriously vulnerable to wind erosion. The physical characteristics of sawdust are to blame – high porosity, fine particle size and loose stacking structure. The high porosity of the piles allow air to easily penetrate and increase the wind’s ability to pick up and disperse particles.

Low density, irregularly shaped particles tend to stay airborne for a longer period of time and travel further due to their increased surface area to volume ratio. In other words, dust travel is related to the speed the wind is blowing at. This means that if the wind speed doubles, the dust will usually travel twice as far. It is fairly obvious that as the wind speed decreases so does the distance the dust will travel.

A wind fence can effectively cut wind speed in the sheltered area to half which dramatically reduces dust distribution. This means that a sawdust pile that is losing 2000lbs of dust a month could theoretically lose less than 250lbs with a well-designed wind fence. The increase in profit follows suit

– the more product available to sell, the more profit available to earn. It’s easy to see that a wind fence

pays for itself in a short time. It’s a win-win situation any way you slice it.

5. Improving Regulatory Compliance: Wind

Fence’s to the Rescue

The cost of regulatory penalties is continually on the rise. In 2023, OHSA announced a monetary increase in fines and in 2024 maximum penalties were increased for a second time9. Depending on the severity of the incident, fines can range from thousands to millions of dollars per incident. Dust is high on the list of non-compliant offences especially in sawmills and timber yards. Take for example a lumber manufacturer in Georgia who was cited with 22 safety and health violations and was divvied out over $279,000 USD in fines. Amongst the violations, accumulation of wood dust was noted10. In late 2024, a sawmill in Washington was fined $126,000 USD for dust accumulation over the maximum allowable 1/8 th inch11. The list goes on and on – regulatory adherence is clearly an ongoing concern within the industry.

The cost of non-compliance puts workers at risk and has a significant fiscal impact on business. With regulations becoming increasingly stringent and fines becoming heftier, those in the industry are in search of strategies to improve and maintain occupational health and safety. Dust is a major contributor to health and safety violations – creating slippery surfaces, reducing visibility, fueling fires and in some cases resulting in deadly combustible dust explosions.

Wind fences offer a low maintenance, set it and forget solution to squash dust. The sheltered area created by a wind fence allows airborne dust to quickly settle and wind speed reduction prevents dust from being picked up and blown around. Wind fences have demonstrated an improvement in local and downwind air quality and significant dust suppression fostering compliance with strict EPA and OHSA requirements. The return on investment is clear – cultivating an environment of regulatory compliance keeps your money in your wallet and creates a safer more productive working environment for employees.

6. Wind Fences: The Investment that Pays You

Back

Dust suppression strategies can be costly to initiate and maintain. Many solutions require ongoing consumables and additional manpower to operate and maintain, adding preventable financial burdens on businesses. Chemical sprays, frequent maintenance, and manpower costs add up quickly and the larger the area to cover, the higher the associated costs. Not to mention the clean up costs associated with pesky dust that travels off site and causes issues for your neighbours and surrounding communities.

Although the initial investment for a custom engineered wind fence may be substantial, they have demonstrated that they quickly pay for themselves in a matter of months without the need to continually inject capital. WeatherSolve wind fences have a proven track record and excellent return on investment. Consider a site that had numerous complaints about dust pollution from its bagasse (dry fibrous material leftover from sugar processing) piles used as biofuel to provide energy for their operations. The site had originally been using a bunker system to control the dust. When wind came in contact with solid barrier created by the bunkers, it went up the wall, accelerated over the top, to create an area of choppy, swirling air on the other side causing dust to get kicked up and carried away by the wind. Then there was the conveyor system, hoppers, and loaders to process the bagasse. This equipment was running 24 hours a day making matters much worse.

We learned earlier that fibrous, less dense materials (e.g. bagasse) tend to stay airborne longer and are very easily transported by the wind. You can only imagine the layers of dust that would end up on homes, vehicles, and buildings in the surrounding area with the site running all day every day! A fine mess indeed.

WeatherSolve was tasked with developing a solution for this dust drama. Computer simulations were used to analyze how particles and wind were behaving at the site and the WeatherSolve team came up Image showing how wind interacts with a solid barrier versus a porous barrier with a solution. A two-section fence with varying heights was designed and installed. One section of the fence acted as an upwind fence to reduce wind speeds and prevent the bagasse from becoming airborne while the second section of the fence acted as a downwind fence to catch those pesky particles that were already in the air. The result was a huge success. The fence not only prevented valuable fuel from blowing away, it prevented the dust from bothering the neighbours. This story has a happy ending with significant money saved in bagasse fuel and no more complaints from the neighbors. Case and point. Wind fences pay you back in all sorts of ways.

7. Saving Sawdust: A Case for Wind Fences

Wind fences have proven effectiveness in reducing dust levels in saw mills and timber yards. Take for example a large plywood producing operation in Western Canada. The mill is located next to a main waterway for ease of product transport. As part of operations, the mill manufactures, stores and ships wood chips; all of which contributes to the risk of off-site transportation of fugitive dust. Haulers and loading/unloading in the chip-handling area were also culprits in in this dust distribution – grinding the dust into finer particles and kicking it up as they traversed. Current dust mitigation measures were simply not up to snuff and WeatherSolve Structures was charged with developing an effective solution to prevent dust migration and reduce product loss.

The solution was further complicated by the recent removal of a row of trees that acted as a downwind barrier and local soil composition. The soil contained sand and silt deposits underlying up to 3m which increased susceptibility to seismic liquefaction. In other words, the soil ran the risk of losing its strength and becoming fluid like.

A thorough evaluation of the site was conducted; taking into account topography, soil composition, wind behaviour and project-specific operational requirements. A wind fence was engineered and designed with a length of 1400ft and varying heights up to 48ft. The panels were made from UV and tear resistant fabric with varying aerodynamic porosities. The fence had a double catchment system to enhance dust control.

The fence was erected in 2006 and not only prevented the spread of dust to the surrounding area but significantly decreased the amount of onsite dust as well. The structure was of such quality that panels only required replacing at almost 20 years post installation. The structure continues to reduce dust and protect the surrounding area.

8. Turning Dust Into Dollars: Revolutionize Your Sawmill

Wind fences are a powerful and eco-friendly way to cut down on dust in timber yards and saw mills. By slowing wind speeds and stopping dust from blowing away, worker health and safety is improved and valuable product is saved. This means higher profits, lower clean up costs, and happier neighbours. Wind fences also make it easier to meet strict safety and environmental rules. As the demand for sawdust and wood products continues to grow, having good dust control in place is critical. Wind fences are an important tool to improve air quality, keep workplaces safe, and offer both financial and environmental benefits in the timber and sawmill industries. If dust is causing a problem for your site or neighbours, a wind fence just might be the solution.

9.References & Reading Material:

1. The Observatory of Economic Complexity OEC “Sawdust, wood waste or scrap” https://oec.world/en/profile/hs/sawdust-wood- waste-or-scrap Accessed March 17, 2025 2. American Cancer Society “Known & Probable Human Carcinogens” https://www.cancer.org/cancer/risk-prevention/understanding- cancer-risk/known-and-probable-human-carcinogens.html Accessed March 31, 2025 3. Fritschi, L., Driscoll, T., “Cancer due to occupation in Australia” Australian and New Zealand Journal of Public Health. Volume 30, Issue 3 June 2006 pp 213-219 https://doi.org/10.1111/j.1467-842X.2006.tb00860.x 4. NIH Cancer Institute “Wood Dust” https://www.cancer.gov/about-cancer/causes-prevention/risk/substances/wood-dust Accessed March 31, 2025 5. Mofidi, A., Tompa, E., Kalcevich, C., “Occupation Exposure to Wood Dust and the Burden of Nasopharynx and Sinonasal Cancer in Canada” Int J Environ Res Public Health. 2022 Jan 20;19(3):1144 doi: 10.3390/ijerph19031144 6. CAREX Canada “Wood Dust Occupational Exposures” https://carexcanada.ca/profile/wood_dust-occupational-exposures/ Accessed March 31, 2025 7. Sharma, R., Chandola, V., Phatak, R., “Sawdust Dryers Market Latest Report 2025” Dataintelo https://dataintelo.com/report/global- sawdust-dryers-market Accessed March 31, 2025 8. Verified Market Reports “Sawdust Granulator Market Insights” https://www.verifiedmarketreports.com/product/sawdust-granulator- market/ Accessed March 31, 2025 9. OHSA “OSHA Trade Release” January 12, 2023 https://www.osha.gov/news/newsreleases/trade/01122023 Accessed April 1, 2025 10. Esler, B., “OSHA Cite Lumber Manufacturer for Combustible Dust as Hazard” Woodworking Network https://www.woodworkingnetwork.com/management/osha-cites-lumber-manufacturer-combustible-dust-hazard Accessed April 1, 2025 11. Washington State Department of Labor & Industries News Release https://www.lni.wa.gov/news-events/article/24-28 Accessed April 1, 2025

Claire Cowie is a seasoned Quality Assurance Manager with over two decades of experience in healthcare and manufacturing. Her career began in pharmacy, where she led teams and honed her skills in quality management systems. As she transitioned to the manufacturing sector, her unique background combines a deep understanding of policy and quality assurance with a keen eye for quality control.

Claire has been instrumental in implementing and cultivating a comprehensive quality control program within WeatherSolve Structures. She has successfully integrated her pharmaceutical background with manufacturing best practices, particularly in areas such as Good Manufacturing Practices (GMP) and ISO 9001 standards. Her unique blend of experience continues to drive innovation and excellence in her role.